Introduction to PPF and Understanding the PPF Curing

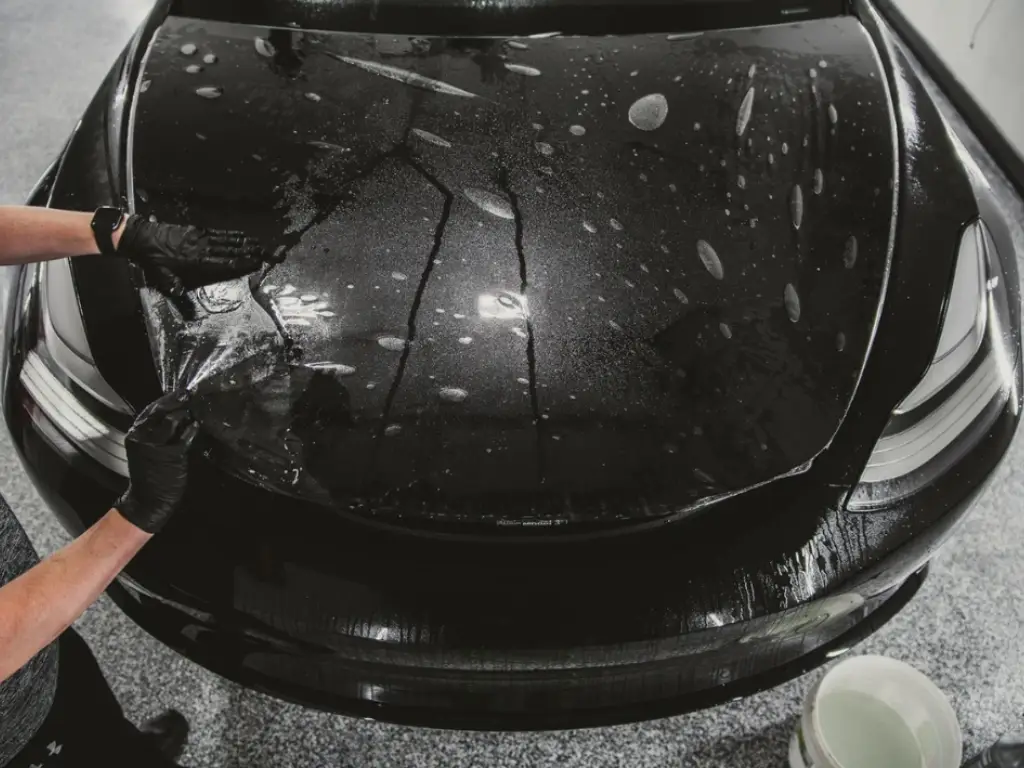

PPF, also known as clear bra, is a thin and transparent material. It repels water and covers the paint surface of a vehicle externally. It protects the vehicle from harmful objects such as stone chips, abrasions like bug splatter, and several water spots, stains, or debris. This phase ensures even attachment of the film to the car’s coat of paint. It thus improves the ability and efficiency of the film.

Different forms of PPF take different durations. It relies on the specific kind of film used. The environmental conditions surrounding the PPF process and the make of the vehicle also play a role. This curing period is essential. It allows them to ensure that the solvents in the film evaporate and the glue activates completely. This step is important. It prevents the film from disappearing during the coating period. Therefore, it ensures that the film achieves most of the protection.

It is important to grasp how to combine these factors. These include the design for a specific vehicle. The goal is to enhance the best level of paint protection and safety of the automobile. This approach also maximizes the outcome. The antiscratch film PPF uses strong adhesive technology. This technology guarantees the film stays in position, even in unfavorable weather. This prevents regular scratches, including swirl marks, that occur on the exterior of the vehicle for a long time. A car owner who understands how the polyurethane coating dries will be able to appreciate the profitable and practical opportunity to install quality PPF on the car.

Factors That Affect How Long Does PPF Take to Cure

Type of PPF

There are many factors that impact the length of time the PPF takes to cure. There are various kinds of PPF, each with distinctive features. Different types of PPF include different factors. These factors include its thickness, the type of adhesive, and additional treatments. Examples of these treatments are ceramic or UV coating.

It is important to grasp how to combine these factors. These include the design for a specific vehicle. The goal is to enhance the best level of paint protection and safety of the automobile. This approach also maximizes the outcome. The antiscratch film PPF uses strong adhesive technology. This technology guarantees the film stays in position, even in unfavorable weather.

On the other hand, there are some PPFs that have been formulated with special bonding substances that dry quicker. Such state-of-the-art adhesives can be very helpful in reducing the cure period without in any way affecting the quality of the film’s protection. For instance, films utilizing fast cure adhesives are able to bond down quicker so that the automobile can be subjected to various conditions earlier.

Several other PPF also contain compounds that are not typical in other materials like the additive for UV curing. This allows the addition of some compounds to the coating of the film, including window tint, when certain lights warm them, which would otherwise take longer to evaporate, thus enhancing the rate of successful integration of the film on the automobile body.

Tip: Various types of PPF are produced by several manufacturers and brands. You must adhere to the manufacturer’s instructions to achieve the best result in terms of application and performance.

Temperature Effects

The course of curing Paint Protection Film (PPF) is greatly influenced by the temperature. The normal temperature range for PPF installation is always from 50°F to 90°F (10°C to 32°C). Within this temperature range, the adhesive remains active and the film is still very much flexible thus it makes the application to be easy. If the temperature goes under 50°F, the adhesive is less effective, making this film much harder to bond. However, if the temperature goes over 90°F, film may be too pliable and too stretched, which may affect the quality of the installation.

For the best results, it is better to adhere to the recommendations given by the manufacturer of PPF in the manual or consider DIY factors affecting the installation. For optimal results, it is important to maintain the work environment within certain limits during the application to prevent such problems as bubbling or wrinkling up loads, which tire the film and could take the entire day if not managed well, thus enhancing its longevity.

Humidity

Humidity levels are particularly critical when curing Paint Protection Film. They impact the bond strength and longevity of the film. In places with high humidity, the water in the air may prolong the cure time of the adhesive. This prolonged cure time can cause the adhesive layer to slip as it ages.An excessive level of humidity can prevent proper coating of the adhesive, making it weak in the long run. This can lead to problems such as lifting or edge peeling of the film.

For best results, it is important to ensure relative humidity levels are maintained between 40% to 60% levels. Any deviation from this level causes condensation or bubbling on the PPF surface. It could result in pleasing images with an uneven distribution of gloss. It may even produce discomforting colors. Deploying PPF under conditions that are either too humid or too dry may compromise the quality of the repairs. Professional installers commonly use dehumidifiers and air conditioners. These devices regulate the air inside during the installation period. This also helps in activating the adhesive properties effectively so that a neat final appearance is obtained, which is durable.

| Factor | Details | Recommendations |

| Type of PPF | Various types, thickness, adhesive type, treatments like ceramic/UV coating. Thicker PPFs cure longer but offer better impact protection. Some PPFs use fast-cure adhesives for quicker bonding. | Follow manufacturer’s instructions for best application and performance. |

| Temperature | Optimal range is 50°F to 90°F (10°C to 32°C). Below 50°F adhesives are less effective; above 90°F, the film may overstretch. | Maintain the temperature within the recommended range during installation. |

| Humidity | Ideal relative humidity is 40% to 60%. High humidity can prolong cure time and cause adhesive issues like slippage or peeling. | Use dehumidifiers or air conditioners to regulate and maintain optimal humidity. |

How can you verify that your PPF has fully cured?

Prior to the sitting of the vehicle’s normal operation, one must ensure that the PPF has completely cured. One can check this by looking at the edges of the film to see if it has lifted up or there are bubbles present in them.

Generally, the presence of these issues means that the film curing did not take place appropriately. Whole curing of film is brick wall smooth surface for obstruction free penetration along with the surface contours with no marks.

To avoid those common problems, the installing personnel often use a squeegee or a microfiber cloth to place the film evenly and prevent the formation of moist and air pockets. In normal cases, after the suggested curing time, they may continue with these inspections to make sure enough curing has taken place. This approval is essential and comes in handy in situations when embarking on further procedures say coating new ceramic coatings which normally requires a dry surface for protection efficacy.

Why Have to Wait for PPF to Cure Before Applying a Ceramic Coating?

Ceramic coatings provide additional protection to the vehicle surfaces, ensuring the integrity of the vehicle’s paintwork. However, one must ensure that PPF cures well before these coatings are installed on top of the PPF. As long as the PPF is a proper non-hazardous layer over the vehicle’s paint, why not wait until the coating hardens completely? Subjecting PPF to a ceramic coating too early may end up causing excessive alteration in adhesion of the PPF. This may cause the film to peel off, or even trap solvents underneath the film and try to trap them. These trapped solvents can influence the bond strength of the film restraining its performance and durability.

Furthermore, the curing process helps the PPF to become flat and patient which is perfect for accepting a ceramic coat. It is also tested that in case the ceramic dust can be removed with a wet rag within the required time and a PPF is applied over the ceramic permanently bonded fully adhered, it can lie continuously on the basematerial PPF. This causes higher adhesion of the coatings and makes sure that even the environment-deteriorating agents like ultra-violet radiation, salt, and pollutant particles penetrate through them. The final outcome is a beautiful finish and added water repelling characteristics that make the car more hygienic and more importantly militarily stature.

Vehicle Usage: When Can You Drive After PPF Installation?

After installing PPF on the hood, we understand you want to step on the gas pedal. While it is safe to drive a vehicle straight after the installation, it is advisable to stay away from heavy rain, heavy-duty, high-pressure cleaners, and direct exposure to the sun for the first 24 hours to ensure the best curing and bonding of the anointed film. This safety precaution enables the film to begin to take its basic position without being within a curing process that may compromise the healing of the film.

As to the fact that it would be vain, during the first week after film installation, it would be the best to avoid. These types of action can shorten the setting period of the adhesive that may leave the film intact. Adhering to these guidelines allows for the film to remain positioned as intended and functional in as far as providing your vehicle’s surface with strong and long-lasting protection.

Such activities are normally taken as preventative measures against potential damages that might result from film exposure to UV or thermal effects. But as is here on the reasonable way of taking PPF, this is where professional installers always emphasize these few caring steps for maximizing PPF advantages lifespan factors cube at the go. It is also because of these that the film is now maintained in the sun up to the day of application as undisturbed in the early stages of curing.

Troubleshooting Common Issues During PPF Curing

Every now and then, when you are curing the PPF, you may observe some minor imperfections like lifting, bubbling, or even slight imperfections. For the most part, these defects are not a reason for alarm and you can usually fix them very quickly. If bubbles appear beneath the film, you can usually work them out with a squeegee or sometimes apply a little bit of heat to help the air bubble underneath the film escape.

This situation is characterized by the edges of the film lifting where there is no adhesion with the film material, which occurs due to environmental conditions such as low temperature or high moisture level. Under these circumstances, you can apply heat and pressure again to reset the adhesive and create a correct joint to the painted surface. When in doubt on how to fix these types of films, it is most advisable to seek guidance from a professional installer to avoid damaging the films.

Maintenance Tips During the Curing Period of PPF

You cannot emphasize enough the importance of taking proper care during the curing period, as it determines the longevity of your Paint Protection Film (PPF) and its protective features on your car. In the first three weeks after installation, avoid placing the PPF in struggle with difficult conditions, such as, surface scratches, aggressive cleaning wipers or chemical cleansers. Rather, they should go for a gentle bath using pH balanced soapy water with a soft microfiber cloth to washing their vehicle. If considering using a pressure washer, it is crucial to avoid the film’s edges to maintain the PPF’s integrity.

In addition, you should avoid exposing the car under trees that may cause bird droppings or tree sap. If for some reason these contaminants touch, or vegetables touched the PPF, they ought to be delicately wiped off immediately to prevent staining. Besides, applying wax regularly and preventing exposure to direct sunlight and stormy weather can contribute to the environmental stabilization of the film.

By observing these maintenance techniques and not neglecting any other PPF issues whenever they arise, you can be certain that you achieve proper adhesion by wiping the PPF after the PPF installation process for effective protection against damage to the vehicle’s paintwork. This careful approach will serve to increase the lifespan of not only the PPF, but also the paint beneath, therefore making the car appear like new for longer years.

Conclusion

Recognizing how long it will take before paint protection film is fully cured is essential in ushering in the full range of protection benefits that the film can offer the automobile. The curing time is relative to the PPF, temperature and humidity levels and it is important to prevent the FPF from deploying and helping it to work as designed design. Moreover, to avoid problems such as bubbling and lifting that normally affect the condition of the car’s paint, it is important to be considerate on the use of PPF and allow it to cure completely.

And most importantly, do not skip the step of allowing the film to cure properly and dry before proceeding with further procedures such as ceramic coating to ensure that everything stays as desired. By adhering to the recommended maintenance procedures for the curing period and rectifying any problems within the time frames, the advantages of PPF will last with your car for defer years.

To conclude, paint protection films are a very good investment for anyone who wishes to protect the surface of their vehicle. Proper application and maintenance allowing PPF, in particular, to perform its fidelity, will protect your vehicle from everyday driving, various elements and make it shiny and new at the same time.

Your Best Try

ClearPro leads as a professional paint protection film manufacturer, specializing in clearPPF that shields your car from scratches and UV damage while enhancing its natural beauty. Their films promise clarity and resilience, making ClearPro the preferred choice for drivers seeking the best in vehicle paint protection. Experience new clarity with ClearPro, where quality meets innovation.