One of the markets that has a high asymmetry of information is the automobile protection market. Hyperbole in marketing e.g. diamond hardness, permanent bond, and armor shield are usually sold to the consumers and in most instances the underlying chemistry and physics is hidden. To make a prudent decision on the way to keep the vehicle in 2026, one has to look beyond the slick brochures and familiarize themselves with the material science of surface protection.

This discourse aims to demolish the terrain of ceramic coating. The chemical processes that enable these products to be distinct amongst the conventional waxes, the comparison of the existing products in the market based on the utility and skill requirements, and the critical analysis of the physical limitations of liquid applications will be discussed. Besides that, we will give a structural perspective of the manufacturing business, contrasting the liquid solutions with the advanced functional films.

It is not merely a catalog of the products but a rigid structure of the Total Cost of Ownership (TCO) and actual performance boundaries of the existing paint protection systems.

Understanding Chemistry: SiO2 vs. Wax vs. Sealants

To understand the value proposition of a ceramic coating, one must first understand substrate interaction. The primary distinction between traditional protectants and ceramic coatings lies in the nature of the bond formed with the vehicle’s clear coat.

The Physics of Adhesion

Organic Waxes (Carnauba):

Traditionally carnauba wax was the norm. This is an organic substance chemically. It is placed over the clear coat when used, and occupies microscopic defects, to a large extent, by physical occlusion. But since it is organic, it is very vulnerable to heat and oxidative damage. Carnauba melts easily in direct sunlight, so it evaporates and decomposes quickly. The connection is loose; it is just a coating of grease on a surface.

Synthetic Sealants:

The sealants are the initial step towards chemical engineering in automobile care. These consist of artificial polymers that combine to create a hard shell. Although they have a higher thermal resistance than wax, their contact with the paint is mostly adhesive, but not cohesive. They are placed on the paint, and the surface tension and weak van der Waals forces keep them stuck.

Ceramic Coatings (SiO2/TiO2):

The paradigm shift takes place here. Ceramic here is the utilization of Silica Dioxide (SiO2) or Titanium Dioxide (TiO2) nanoparticles in a resin carrier liquid. On application, the carrier solvent evaporates (flashes) and the nanoparticles cross-link. Compared to wax or sealants, high quality ceramic finishes bond with the clear finish covalently.

The coating is anchored at a molecular level using the microscopic pores of the clear coat and then crystallizes. It is not just a surface coating, but a semi-permanent functional coating of the paint system itself. This produces a surface with much lower surface energy that is reflected in hydrophobicity (water repellency) and chemical resistance (pH tolerance 2-13).

The “9H Hardness” Fallacy

There is a serious myth-busting explanation needed on the measure of hardness. Marketing literature often states that it is 9H Hardness, and the consumer assumes that his/her car will be as hard as a diamond (10 on the Mohs scale).

This is a basic category error.

The 9H in automotive coating is the Wolff-Wilborn Pencil Hardness Test, not the mineralogical Mohs scale. A graphite pencil of hardness 9H is pressed on the surface at a 45-degree angle in this test. When the coating is resistant to being scratched by the graphite, it is considered 9H.

To put this in perspective:

- Talc (softest mineral) has 1H on Mohs scale.

- The fingernail is around 2.5H on the Mohs scale.

- A 9H pencil is much softer than a normal glass window.

Thus, although a ceramic coating provides a quantifiable level of resistance to light marring (e.g. swirl marks during washing), it is structurally unable to withstand high-impact forces. It is not an impenetrable force field but a sacrificing chemical layer.

Best Products by Skill Level and Budget

In 2025 and moving into 2026, the market has segmented efficiently based on the user’s marginal utility—balancing the cost of application (time and effort) against the duration of the benefit. We can categorize the “best” products not by a single metric, but by their suitability for specific consumer profiles.

Best for Beginners: Spray Ceramic Hybrids

Target Demographic:

The efficiency-seeking consumer. This person probably does not have a garage, special lighting, or a dual-action polisher. The opportunity cost of spending a whole weekend in detailing is too expensive.

Market Leaders:

- Turtle Wax Hybrid Solutions Ceramic Spray Coating.

- Meguiar’s Hybrid Ceramic Wax

Analytical Review:

These products are the democratization of the SiO2 technology. Manufacturers have achieved a high solid content (the real concentration of silica) by lowering the solid content and loading the solvent and polymer carrier to produce a product with high lubricity.

The first benefit in this case is the margin of error. Conventional finishes need to be wiped off; otherwise they dry in ugly ridges which have to be removed by sanding. Spray hybrids do away with this risk. You spray, rinse or dry.

- Durability: 3 to 6 months.

- Hydrophobicity: It is surprisingly high at the beginning, but it reduces linearly with the number of wash cycles.

- Value Proposition: They give 70 percent of the visual appeal of a real coating at 10 percent of the work. In case the application fails, the correction cost is insignificant, it will just be washed away in time.

Best with Passion: Glass Bottle Coatings, High Solid

Target Demographic:

The “Detailer.” The process itself gives utility to this person. They can enjoy a controlled setting (garage), ready to spend 8+ hours on labor, and they know the significance of lighting. They want the best combination of price and performance.

Market Leaders:

- CarPro CQuartz UK 3.0 (Industry standard)

- Gtechniq Crystal Serum Light (CSL)

Analytical Review:

These are High-Solids coating. They are packed in small glass vials since the concentration of SiO2 is much higher (usually more than 50-70%).

- Application Dynamics: These are products that are sensitive to atmospheric conditions. Humidity and temperature determine the flash time – the time within which you must level the coating before it starts to cure.

- CarPro CQuartz UK 3.0: It was designed to work in changing climates, so it is not very demanding, but needs to be buffed. It is also famous for its resistance to chemicals.

- Gtechniq CSL: Has a little more working time, which is not as stressful to the DIYer. It is commended on its excessive gloss and smoothness.

- Performance: On curing, they create a quantifiable layer (around 0.5 to 1 micron) that persists 1.5 to 3 years.

- Visual Effect: On dark paint, these finishes enhance the color, giving it a wet appearance because of the manner in which the glass-like layer reflects light.

Best of the Best: Professional-Grade Services

Target Demographic:

The low time preference and high liquidity consumer. They are buying risk insurance and labor assurance instead of a chemical product.

Market Leaders:

- Ceramic Pro (Gold/Ion)

- Modesta

Analytical Review:

These products are not sold in the shelf. This man-made scarcity plays a role of quality control. The difference is in the process of curing and coating.

- Process: The accredited installers apply short-wave Infrared (IR) lamps to the panels to bake the coating. This increases the speed of cross-linking and makes sure that maximum hardness is attained instantly, as opposed to taking weeks to cure naturally.

- Layering: Professional packages may include several layers of base coat to make them thick and a special topcoat that is hydrophobic.

- The warranty: The premium price (usually 1,500 -3,000) is an insurance policy. It includes the work of yearly maintenance and re-application in case of failure of coating.

The “Invisible” Cost: Why Prep Work Matters More Than the Product

The basic fallacy in economic calculation in the case of ceramic coating is that the price of the liquid (the variable cost) is given importance without the consideration of the fixed cost of surface preparation.

The reflection of light determines the optical clarity of a vehicle. Scratches make light (diffuse reflection) scatter, making the paint appear dull. A coating made of ceramics is clear. When you put a coating over swirls, scratches or oxidation, you are basically placing the flaws under a sheet of glass. You add the longevity of the flaw.

The equation of a perfect finish is 90% Preparation, 10% Protection.

The Paint Correction Requirement

Before a high-solids coating can be applied, the substrate must be surgically clean and flat. This involves a rigorous workflow:

- Chemical Decontamination: Using iron removers (like CarPro IronX) to dissolve embedded ferrous brake dust.

- Mechanical Decontamination: Using a clay bar to shear off bonded contaminants (overspray, tar, sap).

- Paint Correction (Polishing): This is the most labor-intensive variable. It involves using an abrasive compound and a machine polisher to remove a microscopic layer of clear coat, leveling the surface to the depth of the deepest scratch.

- Panel Wipe (IPO): Using Isopropyl Alcohol to strip all polishing oils.

The Hidden Costs

If a consumer decides to DIY a “glass bottle” coating, the ledger looks like this:

- Coating cost: $80

- Dual Action Polisher: $150

- Pads and Compounds: $60

- Microfiber Towels (high grade): $40

- Prep Chemicals: $40

- Labor Time: 10-15 hours.

Therefore, the statement “I coated my car for $80” is economically false. The true resource allocation is significantly higher. If one is unwilling to invest in the prep work, the high-end coating is a misappropriation of resources; a spray wax would yield a better return on investment.

The “Graphene” Variable: Marketing Gimmick or Material Evolution?

When you are looking at the ideal coating in 2026, Graphene is bound to come up in your search. The marketing literature states that these finishes are lighter than steel and harder than diamond. However, does it actually protect your paint when you add a carbon powder to your liquid bottle?

The Chemistry: It is Still a Ceramic.

First, let’s clear the air. Nearly all Graphene Coatings available in the market are essentially SiO2 (Ceramic) coatings with Reduced Graphene Oxide (rGO). Consider it as concrete reinforcement. The ceramic resin is concrete; graphene is steel rebar. You are not rubbing a piece of pure carbon on your car; you are rubbing a coating of ceramic that is doped with carbon particles.

The Actual Benefit: Heat Dissipation.

Although the arguments of extreme scratch resistance are mostly overstated (it is still a micron-thin liquid) Graphene does address one particular weakness of traditional ceramics: Heat Retention.

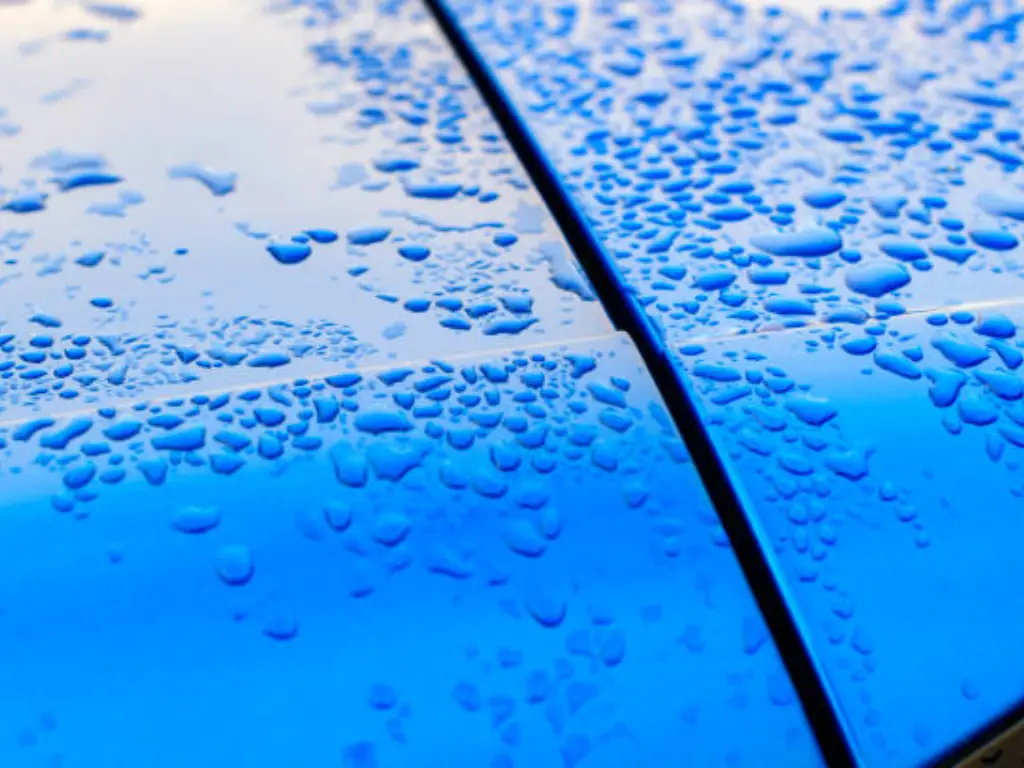

- The Ceramic Problem: Traditional SiO2 has a heat retention property. This heat is used on a hot, black hood where the heat is used to dry water beads, bake minerals into the paint (Water Spots).

- The Graphene Solution: Graphene is a good thermal conductor. It facilitates the dispersion of surface heat.

- The Conclusion: A surface that is a bit cooler to the touch which greatly diminishes the chances of water spotting (hard water etching).

Buyers Guide: When to use Graphene?

- Buy Graphene When: You are living in a hot climate, your car is dark and you cannot get rid of water spots. The additional price is explained by thermal properties.

- Use Standard Ceramic When: You value glossiness to the extreme. Since Graphene particles are grey/black, some users have noted a slight dulling of the glass-like shine with a pure, clear coating of SiO2.

What They Don’t Tell You: The Physical Limitations of Liquid Coatings

In the interest of full disclosure and managing expectations, we must address the structural limitations of liquid ceramic technology. While chemically robust, they are physically frail.

The Rock Chip Reality: Why “9H Hardness” Won’t Save You

We must return to physics. Kinetic energy can be defined as KE = 1/2 mv^2.

At highway speeds (60mph+), the transfer of energy is significant when a small grain of gravel hits a vehicle.

The thickness of a ceramic coating is about 1-2 microns. In comparison, a normal sheet of paper is 100 microns thick.

No matter the rating of the pencil in terms of its hardness (9H), a layer 1/50 th the thickness of a human hair has a zero structural capacity to absorb or dissipate the kinetic energy of a rock impact. The force will break the coating and go through the clear coat and the base coat, creating a rock chip.

A ceramic coating is of no use in terms of utility when your main objective is to avoid stone chips.

Environmental Factors: Water Spots and Chemical Etching

Hydrophobicity is paradoxical. We want high contact angles (tight water beads) to be aesthetically attractive and self-clean. Nonetheless, in some settings, it is harmful.

When a car is parked outside in a place where there is hard water (calcium-rich rain) or in a place where there are sun showers, the tight beads become magnifying lenses. The sun heats and the water evaporates leaving behind concentrated mineral deposits. Due to the tightness of the bead, the deposit is concentrated in a very small area, which can cut into the coating and the clear coat.

Under such particular environmental circumstances, a hydrophilic (water sheeting) behavior could be even better than a hydrophobic (water beading) one, but the market is infatuated with the latter.

A Manufacturer’s Insight: The Evolution from Liquid Coating to Functional Film

We have determined that liquid ceramic finishes are wonderful in regard to chemical resistance and easy cleaning, but have two fundamental weaknesses:

1. Lack of Consistency: The outcome is wholly dependent on the environment of the installer (garage humidity, dust, lighting).

2. Absence of Impact Resistance: Microns are unable to prevent rocks.

Being a manufacturer of high performance automotive films, ClearPro takes a materials engineering approach to surface protection. We do not consider the coating as a finishing touch applied in the garage, but as a part of a carefully-made system.

The development of paint protection does not lie in a bottle, but in Functional Film.

The Logic of One Product, Two Solutions

Why put a liquid coating on your paint when you can put a physical shield on which is pre-coated in a medical-grade facility?

ClearPro has incorporated the advantages of ceramic nanotechnology into the Thermoplastic Polyurethane (TPU) matrix. This is the ClearPro Advantage:

1. Polyoptico™ Difference: Variable vs. Precision

When you put on a liquid coating, you are struggling against entropy–dust, irregular wiping, and curing differences.

The manufacturing of ClearPro films is done in a 3,000 square meter Class 1000 Clean Room. It is a production setting that is similar to the production of electronic or medical devices.

- Zero Orange Peel: The texture of standard factory paint is usually an orange peel (Ra 0.150.25 µm). This texture is fixed in place by liquid coating, though our Polyoptico™ coating structure is used in ClearPro film, with a roughness of the surface (Ra) of 0.05 µm or less.

- The Findings: A 60 degree Gloss Unit (GU) of 95, which is higher than the industry average of 80-82. With the use of ClearPro, you are basically polishing your car with a mirror-flat finish that no liquid can be applied by hand.

2. Eternal Hydrophobicity and Self-Healing

Liquid coating wears out ultimately since it is subjected to abrasion. The topcoat of the film is cross-linked with the hydrophobic properties of ClearPro.

- Data-Driven Performance: Our movies have a water contact angle of 105 or more after 2,000 hours of strenuous Xenon aging tests (SGS Certified).

- The Self-Healing Mechanism: This is the vital separation of liquid coatings. When you scratch a ceramic finish, it remains scratched. When you scratch ClearPro film, the thermodynamic characteristics of the TPU enable it to reflow. ClearPro survived more than 10,000 abrasion cycles with more than 90 percent efficiency in laboratory testing with a copper brush and heat.

3. Structural Integrity (The Rock Chip Solution)

In contrast to the 2-micron thickness of a liquid coating, the films of ClearPro offer a significant physical barrier (Total Thickness of >8 mil) and greater than 400 percent elongation rates. This absorbs the kinetic energy of the road debris, and the underlying paint is not chipped.

Manufacturer’s Conclusion:

We have IATF 16949, ISO 9001 and ISO 14001 certifications not to hang on a wall, but to ensure that the protection you purchase is consistent in its chemicals and physically better. A bottle is good enough in case you want chemical resistance. When you want a permanent, self-healing, impact-resistant shield that has passed the 50,000 km test run of the Nordic freeze to the Middle East heat, the answer is ClearPro Functional Film.

Living with Ceramic Coating: Maintenance and Aftercare

Whether you choose a liquid coating or a functional film like ClearPro, the laws of thermodynamics still apply: systems degrade without energy input. “Maintenance-free” is a marketing myth.

The “Topper” Strategy

To extend the life of the base layer (the coating or the film), one should use a sacrificial layer, often called a “Topper.” This is usually a silica-based spray sealant applied every 2-3 months. It takes the brunt of the environmental abuse—UV rays, bird droppings, road salt—preserving the expensive base layer beneath.

The Wash Protocol

- Avoid Automatic Washes: The nylon brushes in automatic car washes act like sandpaper. They will abrade the coating and eventually strip it.

- The pH Reset: If you notice your coating or film is no longer beading water, it often hasn’t failed; it is merely “clogged.” Road film and mineral deposits can mask the hydrophobic surface. A wash with a slightly acidic shampoo (or a dedicated “Descaling” soap) can dissolve these minerals and “unclog” the coating, restoring its hydrophobic properties.

Final Verdict: Total Cost of Ownership Analysis

Rational economic decision-making requires looking beyond the sticker price. We must evaluate the Total Cost of Ownership (TCO) over a 5-year ownership cycle of a new vehicle.

Below is a comparative matrix to assist in your decision:

| Feature | DIY Ceramic Spray | Professional Ceramic Coating | ClearPro Functional Film (PPF) |

| Initial Cost | Low ($20 – $50) | High ($1,000 – $2,500) | Premium ($3,000+) |

| Durability | 3 – 6 Months | 2 – 5 Years | 10 Years (Warranty) |

| Chemical Protection | Moderate | Excellent | Excellent (Pre-Coated) |

| Physical Protection | Zero (No Chip Protection) | Zero (No Chip Protection) | High (Stops Rock Chips/Scratches) |

| Self-Healing | No | No | Yes (Thermoplastic) |

| Maintenance Effort | High (Reapply quarterly) | Medium (Annual inspections) | Low (Wash & Go) |

| 5-Year TCO | High Labor / Low Capital | High Capital / Moderate Labor | High Capital / Zero Risk |

The Verdict

- Choose DIY Spray Hybrids if your budget is tight, you enjoy washing your car frequently, and you accept that your car will eventually get rock chips.

- Choose Professional Ceramic Coatings if you want a show-car shine and easier cleaning, and you drive in an environment with low risk of physical debris.

- Choose ClearPro Functional Film if you view your vehicle as an asset to be preserved. It is the only option that addresses the physical reality of driving—rocks, scratches, and abrasion—while providing the chemical benefits of a ceramic coating. It effectively renders the “Liquid vs. Film” debate obsolete by combining both into a factory-perfected solution.

In the analysis of 2026, the best “coating” is no longer a liquid; it is a film.